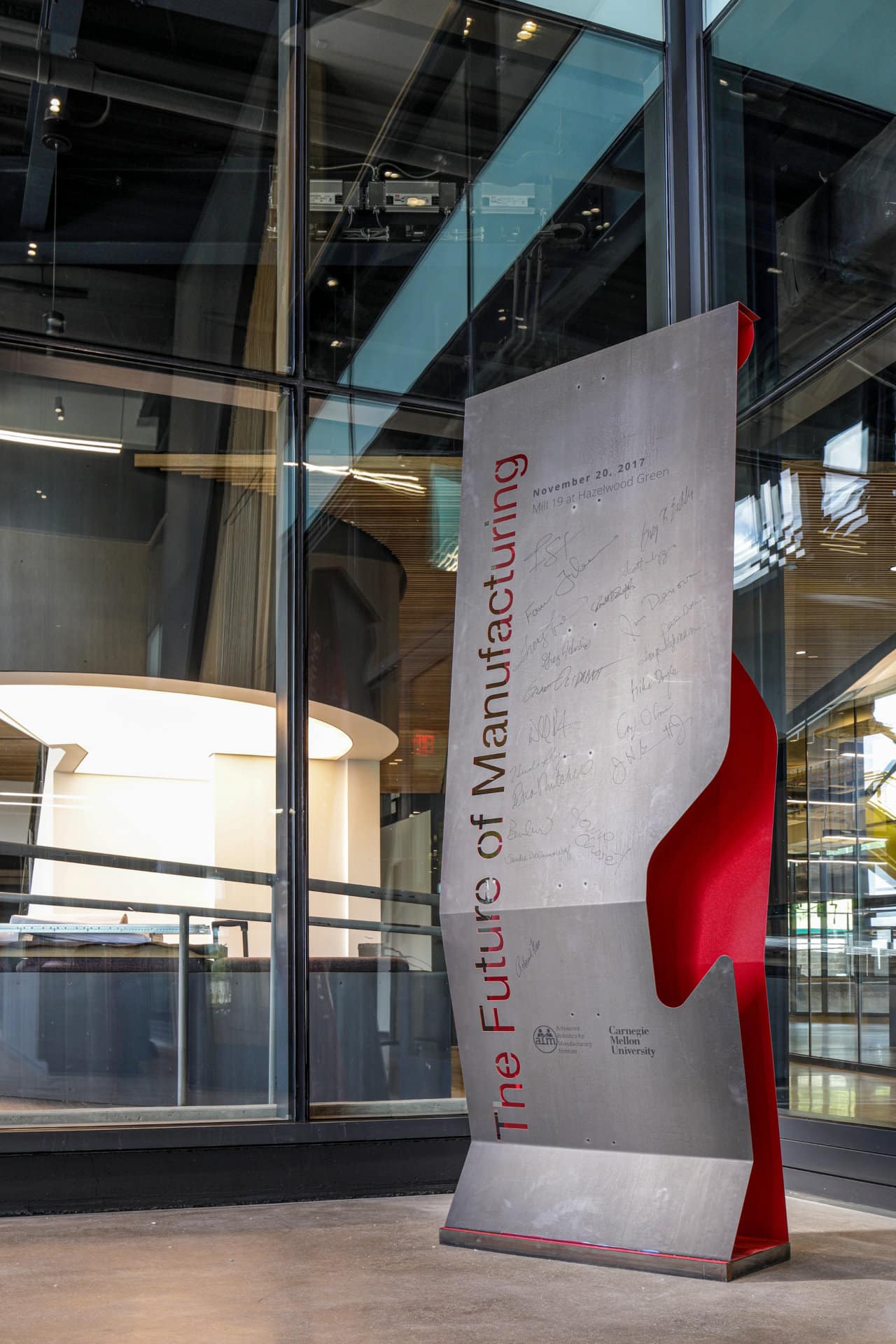

Located within the Hazelwood Green Development, Carnegie Mellon University (CMU) at Mill 19 exists at the intersection of industry, research and education and seeks to build inter-connectivity to pull people out of siloed thinking. Flex Labs offer space for incubator initiatives and promote collaboration amongst industry partners with fenestrated collaboration pods for visibility into and out of the space. The high bay is a 10,000 sq. ft., open workshop for large robotic equipment. A 10-ton crane provides easy equipment movement, making the space highly adaptable to shifting needs. At the end of the high bay, a large curtain wall looks out onto Hazelwood Green’s Public Plaza — the heart of the new development.

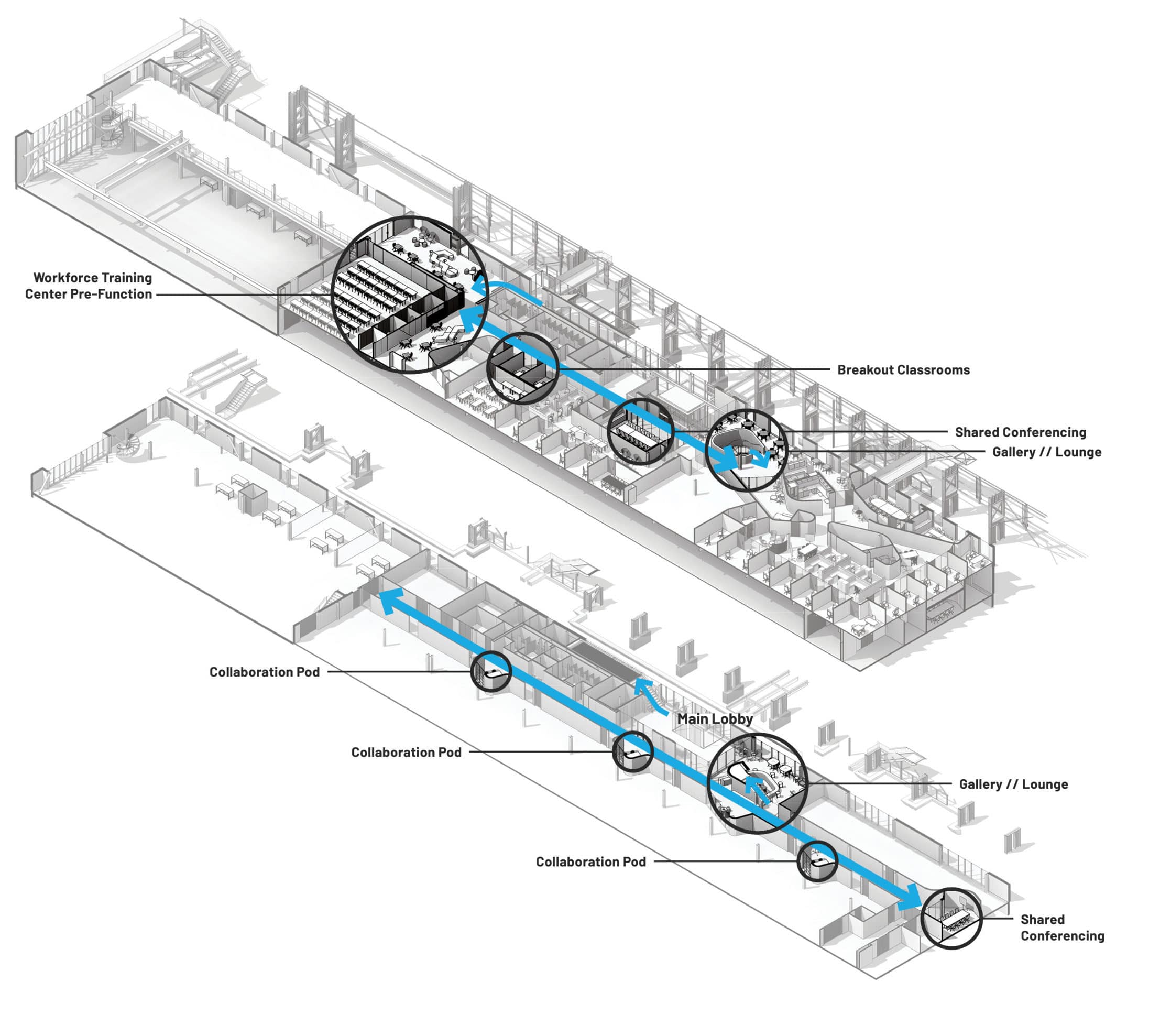

CMU’s collaborative spirit is woven into the interior design strategy, with flexible spaces to support the nimble, interdisciplinary work required to make the future of manufacturing a reality. A series of interconnective spaces within the collaboration network, including a gallery stair, lobby, and high bay flex space balcony provide clear sight lines and visual variability, showcasing the diverse program. This interconnected, open workplace fosters collaboration across departments, making this a bustling hub for creativity with plenty of visual stimulation.

Sweeping views to the surrounding green space, outdoor balconies, and patios support wellness and a connection to nature. Fluid, organic forms serve as a recurring motif throughout the space, encouraging movement and creating a more human-centered environment. The layered and angled geometry serve as a distinguishable language within the space, creating dynamic and holistic connections within the building’s network.